Heavy duty boom

Heavy Duty Boom (HDB)

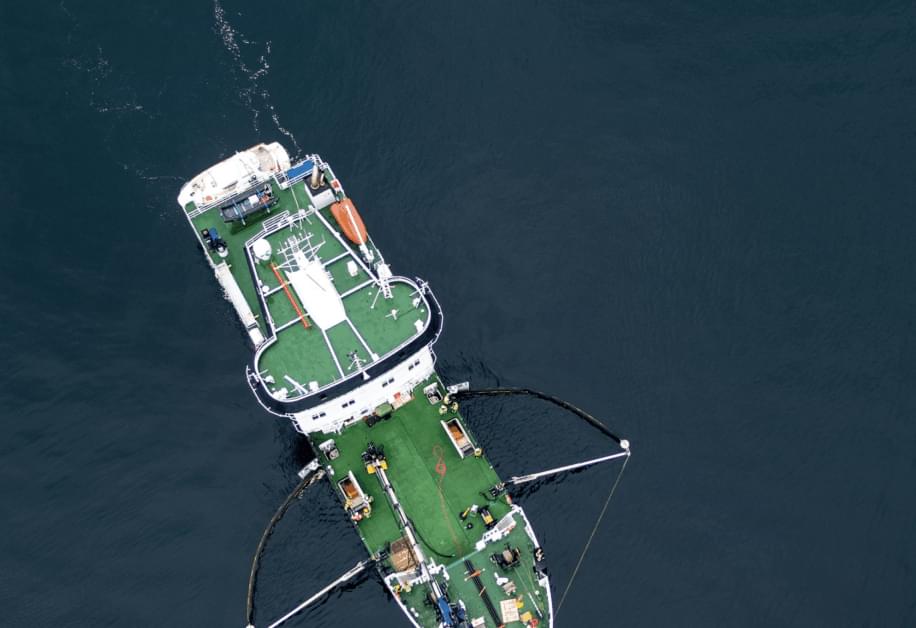

The Heavy Duty Boom is a robust and durable air-inflated boom that covers the increasing demand for offshore operations and for permanent installations at e.g. exposed ports, oil terminals, refineries and power plants. Moreover, the HDB can be utilized in all climatic conditions and environments, including Arctic scenarios.

HDB Boom is extremely durable and reliable in the most critical situations!

How it works

The Lamor Heavy Duty Boom (HDB) is most commonly stored on a Boom Reel and capacity can range from 200m to 300m depending upon the overall size of the boom. A powerpack allows the boom reel to deploy the boom into the water and retrieve the boom back onto the reel for storage.

As the HDB boom is being deployed operators fill each individual air chamber with air from a backpack style air blower or integrated blower for buoyancy. Trained operators can deploy 250m of Heavy Duty Boom within 30 minutes.

The boom is manufactured with either two layers of synthetic fabric vulcanized together with four layers of UV and oil resistant synthetic rubber or heavy-duty flexible neoprene material. The stiffeners, anchoring points, and ASTM fixing plates are vulcanized between the fabric layers of the boom. These features ensure a robust structure, in addition to easy cleaning and maintenance.

The boom is equipped with yellow stripes and reflectors for improved visibility. The HDB boom’s ballast is a hot-dip galvanized steel chain that gives strength and skirt support, The patented Lamor F1 air valve makes the inflation and deflation by a single operator of the HDB significantly easier and quicker than other valves on the market. The F1 air valve features flat design with an incorporated airlock without removable parts. The HBD neoprene option utilizes Munson style air valves.

The HDB preferred end connector is ASTM; however can also be stainless steel hinge and pin if required.

Features

- For use in harbors, offshore, permanent installations and oil sweeping operations

- Patented F1 air valves for easy inflation and deflation by single operators

- Robust and extremely durable¨

Scenarios of use

- Coastal

- Port, harbor & terminal

- Offshore

Related equipment

| Technical Specifications | HDB 900/50-100m | HDB 1200/50-100m | HDB 1500/50-100m | HDB 1800/50-100m | HDB 2000/50-100m |

|---|---|---|---|---|---|

| Length (section) | 50-100m / 164-328 ft | 50-100m / 164-328 ft | 50-100m / 164-328 ft | 50-100m / 164-328 ft | 50-100m / 164-328 ft |

| Height (deflated) | 900 mm / 35 in | 1200 mm / 47 in | 1500 mm / 59 in | 1800 mm / 71 in | 2000 mm / 79 in |

| Weight | 8.1 kg/m / 5.4 lbs/ft | 10 kg/m / 6.7 lbs/ft | 12.1 kg/m / 8.13 lbs/ft | 15.9 kg/m / 10.68 lbs/ft | 17.2 kg/m / 11.56 lbs/ft |

| Freeboard | 350 mm / 14 in | 440 mm / 17 in | 445 mm / 18 in | 560 mm / 22 in | 560 mm / 22 in |

| Draft | 450 mm / 18 in | 560 mm / 22 in | 848 mm / 33 in | 960 mm / 38 in | 1160 mm / 46 in |

| Buoyancy / weight ratio | 8:1 | 9:1 | 8:1 | 11:1 | 10:1 |

| Air Chamber length | 3m / 9.8 ft | 3m / 9.8 ft | 3m / 9.8 ft | 3m / 9.8 ft | 3m / 9.8 ft |

| Base Fabric | EP 400 | EP 400 | EP 400 | EP 400 | EP 400 |

| Fabric tensile strength | 20 000 N/5 cm / 354 lbf/in | 20 000 N/5 cm / 354 lbf/in | 20 000 N/5 cm / 354 lbf/in | 20 000 N/5 cm / 354 lbf/in | 20 000 N/5 cm / 354 lbf/in |

| End connector | ASTM F962 as standard | ASTM F962 as standard | ASTM F962 as standard | ASTM F962 as standard | ASTM F962 as standard |

Stay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.