Water and wastewater

Transforming water treatment for a thirsty world

As the International Panel on Climate Change (IPCC) reports, nearly 80% of the global population already faces water security challenges. With the climate crisis exacerbating water scarcity, it's more crucial than ever to invest in robust water treatment solutions to bolster resilience and secure water resources for the future.

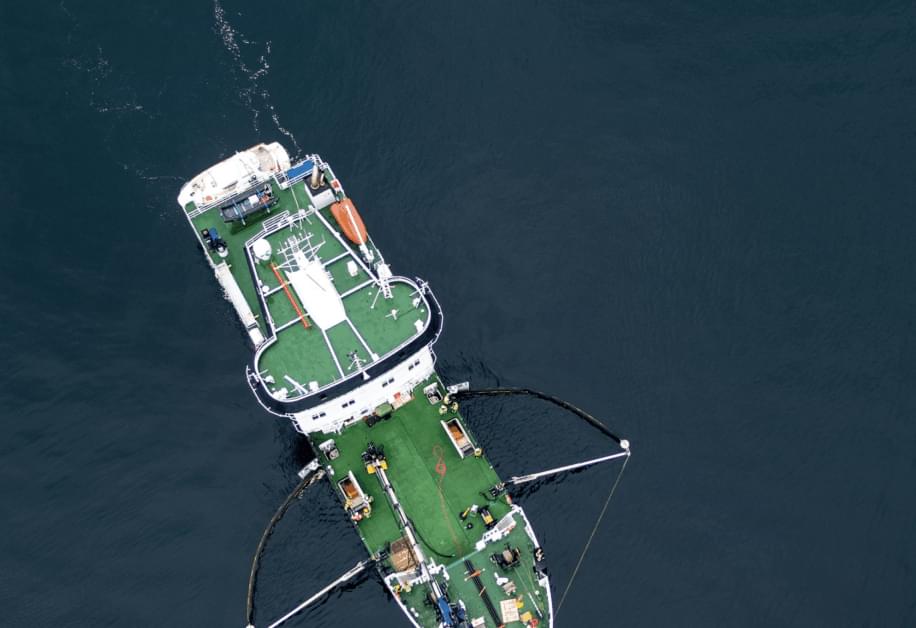

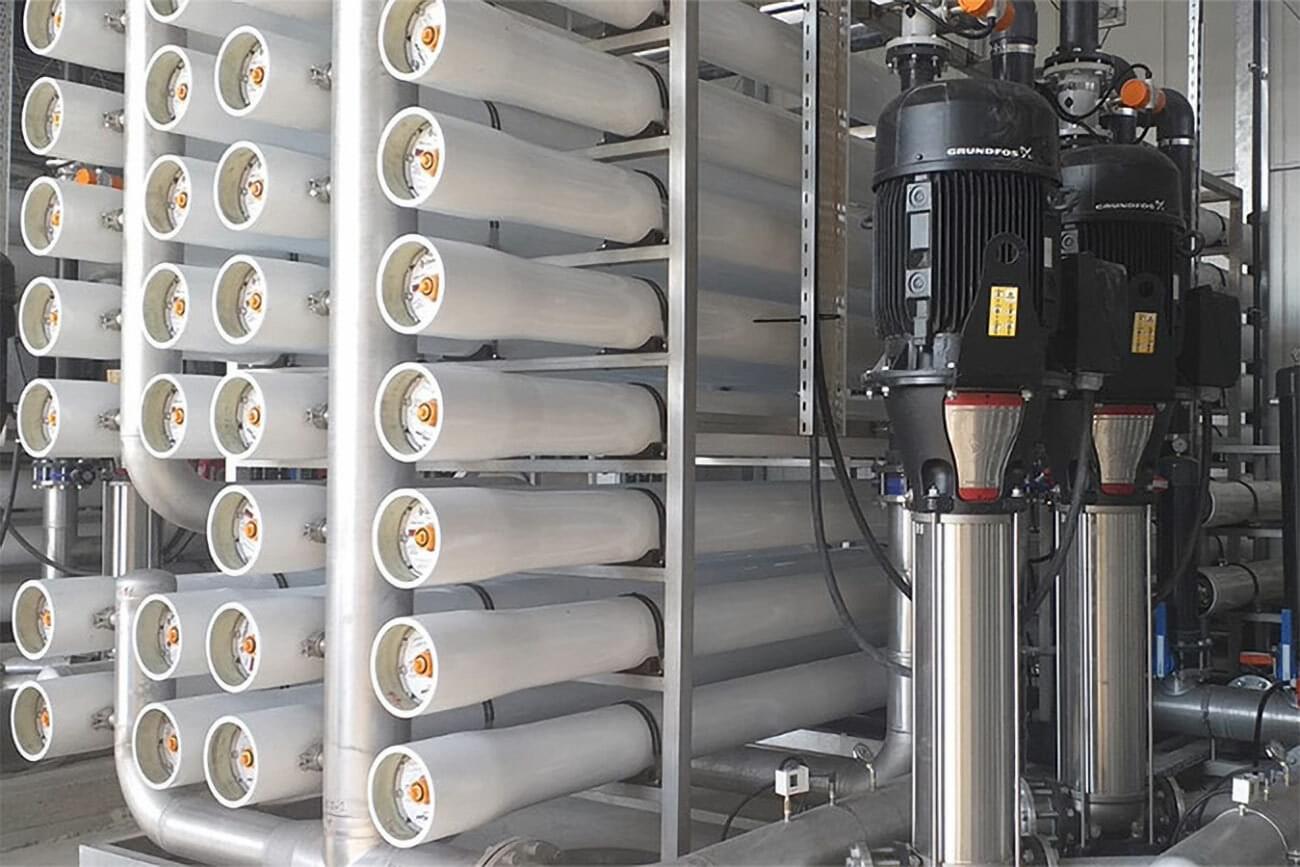

At Lamor, we take pride in our deep-rooted expertise in water purification. Our journey began with oil spill response technology and has since evolved into a versatile array of cutting-edge solutions for wastewater processing and potable water applications. As a dedicated partner at the forefront of Managed Aquifer Recharge (MAR) initiatives, we're devoted to delivering ground-breaking water treatment options.

Our ability to address diverse water treatment challenges is something that fills us with pride.

Discover more about our typical water solution projects, including:

Interested in our solution?

Contact our experts and let's work together for a cleaner, more sustainable future.

Contact usStay in the know

Sign up for our newsletter to learn more about innovations enabling the survival of our dear planet.