Impact Studies

Our latest steps

towards a clean planet

Impact studies

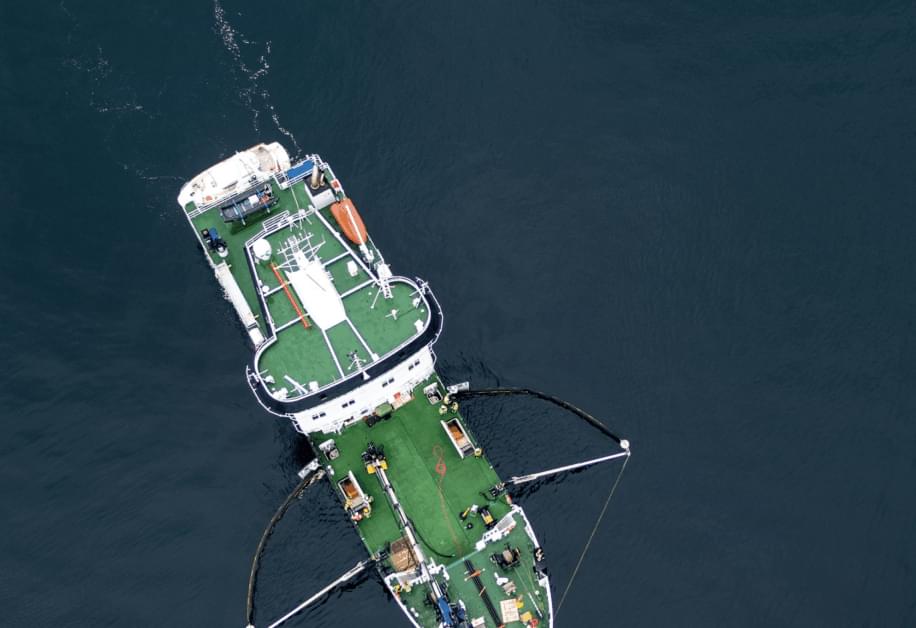

Restoring Kuwait’s soil by cleaning up world’s biggest anthropogenic oil spill

In 2021, Lamor entered into two contracts in consortium with Khalid Ali Al-Kharafi & Bros. Co (KAK) for soil remediation projects in northern and southern Kuwait. The projects have already begun with necessary preparations underway to initiate the first phase of field works.

Read more

03.12.2025

Inderes-TV visits Lamor’s Kilpilahti circular oil plant as mechanical installation work nears completion – watch video!

Read more

21.11.2025

Growing Arctic traffic increases pressure on oil spill response

Read more

17.11.2025

Lamor and FN Holdings deliver incident management training for Azule in Angola

Read more

04.11.2025

Lamor delivers OPRC (IMO) Level I & II Training Course in Panama

Read more

27.10.2025

Lamor trains P&O management and field teams at Port of Caucedo, Dominican Republic

Read more

21.10.2025

Lamor participates in National Maritime Security Exercise in Oman

Read more

15.10.2025

Lamor enhances oil spill response capabilities for fisheries in Northern Peru

Read more

14.10.2025

Lamor Kuwait Soil Remediation Project wins award for Environmental & Sustainability Excellence

Read more

06.10.2025

Lamor joins Repsol for Beach Cleaning Volunteering Day in Peru

Read more

06.10.2025

Building readiness together: Lamor and WWF Finland train volunteers for Oil Spill Response

Read more

22.09.2025

Lamor inaugurates Service Center in Saudi Arabia

Read more

26.08.2025

Giving the Earth a makeover: Responsible waste management of trade-reject cosmetics

Read more

26.08.2025

Lamor delivers OPRC (IMO) Training at PetroChina’s Benin Project

Read more

30.06.2025

Lamor delivers skimmers to Sonatrach in Algeria

Read more

10.06.2025

Lamor delivers rapid oil spill response support for vessel operation in Netherlands

Read more