Impact Studies

Our latest steps

towards a clean planet

Impact studies

Restoring Kuwait’s soil by cleaning up world’s biggest anthropogenic oil spill

In 2021, Lamor entered into two contracts in consortium with Khalid Ali Al-Kharafi & Bros. Co (KAK) for soil remediation projects in northern and southern Kuwait. The projects have already begun with necessary preparations underway to initiate the first phase of field works.

Read more

18 Apr 2024

Lamor conducting oil spill response exercise at Santos Mardones, Punta Arenas

Read more

09 Apr 2024

Finnish Ambassador visits Lamor bioremediation project in Chile’s Magallanes region

Read more

25 Mar 2024

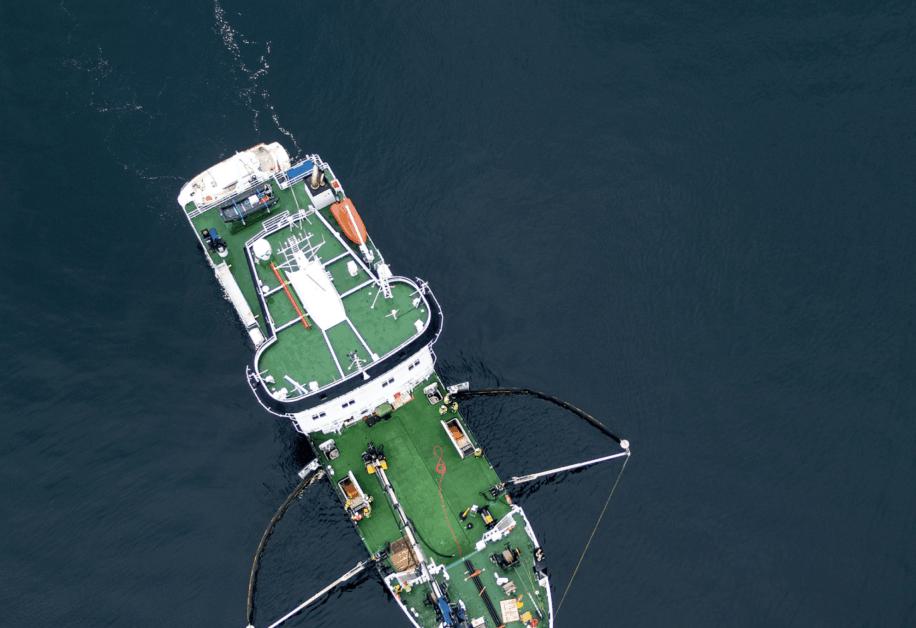

Spanish Coast Guard's new vessel equipped for oil spill response

Read more

06 Mar 2024

Lamor winning the prestigious Contractor HSSE Performance award in Kuwait

Read more

01 Mar 2024

Strengthening maritime preparedness: Tier II drill success at Port of Duqm in Oman

Read more

27 Feb 2024

Riyadh's Environmental Compliance Forum: Vision 2030 in focus

Read more

15 Feb 2024

Successful remediation of hydrocarbon-contaminated sites in Ecuador

Read more

14 Feb 2024

Commissioning and training of OSR equipment in Caucedo port, Dominican Republic

Read more

06 Feb 2024

Consulting program elevates Bilbao’s maritime preparedness

Read more

31 Jan 2024

Lamor's innovative container solutions for oil spill response and environmental protection

Read more

18 Jan 2024

Lamor rescuing marine ecosystems and communities after history's largest marine oil spill

Read more

08 Jan 2024

Innovative Sternmax 10 skimmer: a game-changer for Arctic oil spill response

Read more

19 Dec 2023

Lamor at Oman Al Nawras 2023 national oil pollution control exercise

Read more

15 Nov 2023

Lamor Peru at field workshop at Paracas Port

Read more

16 Oct 2023

Lamor providing quick response services to minimize the effects of environmental impact at Repsol’s oil refinery in Peru

Read more